Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

How can we help you?

The food industry faces around 1.3 billion tonnes of food wasted or lost annually worldwide. Vacuum technology is playing a vital role in various aspects of food technology. Amongst the various aspects, vacuum packaging is gaining prominence mainly due to its ability to increase the longevity of food by reducing the growth of bacteria and fungi. Similarly, vacuum cooling helps keep fruit and vegetables fresh directly after harvesting by enabling food containers to be evacuated to pressures of > 6 mbar. Vacuum drying helps preserve fresh fruit and meat through Vacuum Microwave Drying. Here the products are heated by microwave to 35-60 deg C while the vacuum pump keeps the pressure around 10 mbar. The water content then evaporates. Through Freeze Drying the products are cooled to -20-40 deg C and the water sublimates at pressures below 0,1 and -1 mbar from the solid phase [1].

Considerable progress has been made in the processing of foods using operations viz. drying, evaporation, distillation, concentration, centrifugation, filtration, irradiation, freeze drying, osmotic drying etc. to get ready to eat food, convenience food, precooked dried food, preserved food. Vacuum technology in direct or indirect ways has played a vital role in carrying out these food processing operations.Food materials like farm fresh fruits and vegetables, meat and flesh foods start deteriorating shortly after harvest due to bacteria, microorganisms, insects in addition to biochemical and physiological changes. Therefore, the availability of food supplies can be increased effectively by using various food process methods in which vacuum is used extensively

The traditional methods of food preservation like smoking curing, pickling, canning and drying can augment food supplies by preventing natural deterioration. But, these methods cause changes in color, taste, flavor, texture and other organoleptic attributes of food. Refrigeration preserves for a limited period. Freezing and quick freezing improves the storage stability. Freeze drying is capable of extending the storage life of foods by two years at room temperature conditions retaining taste, flavor and other original properties of foods. Long term storage is affected by using suitable packaging materials, viz. high and low density polyethylene, cellophane, aluminum laminate pouches or nylon bags.

Dehydrated foods provide many advantages like long shelf life and low transportation costs. Many innovative methods have been developed during the last two decades which have enabled traditional dishes to be prepared in readymade form. Prominent among them are precooked dehydrated rice, fruit juice powders and dehydrated vegetables. These products require simple methods of reconstitution. Freeze dried products can serve as a buffer to stock high quality materials for future needs.

The process of osmosis for improved dehydration of fresh fruits seems quite attractive. In the first instance partial drying of fruits upto 50% can be carried out by either air or vacuum drying. As a result the product is subjected to heat treatment for less time during drying and hence the quality of the product is improved to a greater extent. Also the amount of heat energy required for final drying is reduced considerably. The properties of the fruits dehydrated by such procedures are quite similar to freeze dried food. In the case of soft and spongy fruits like banana (ripe) and strawberry, the fruits do not collapse during vacuum drying. The sourness of strawberry due to acids gets reduced because of leaching by syrup and deposition of sugar on the outer surface of the fruit. There is a big scope for use of this method for dehydration of other tropical fruits like guava, sapotas, custard apple, papaya etc.

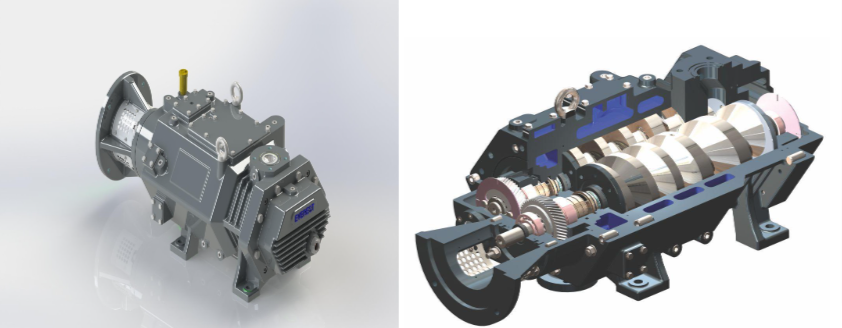

Dry Claw/Screw pumps in food industry applications are more often replacing wet pumps. Oil sealed rotary vane pumps have been the preferred pumps for the food industry for a very long time. The major drawback of rotary vane pumps is the risk of oil spilling out and polluting your workspace or, even worse, your food. Dry Vacuum Pumps avoid these risks and ensure product freshness [2].

Advantages of Dry Vacuum Pumps

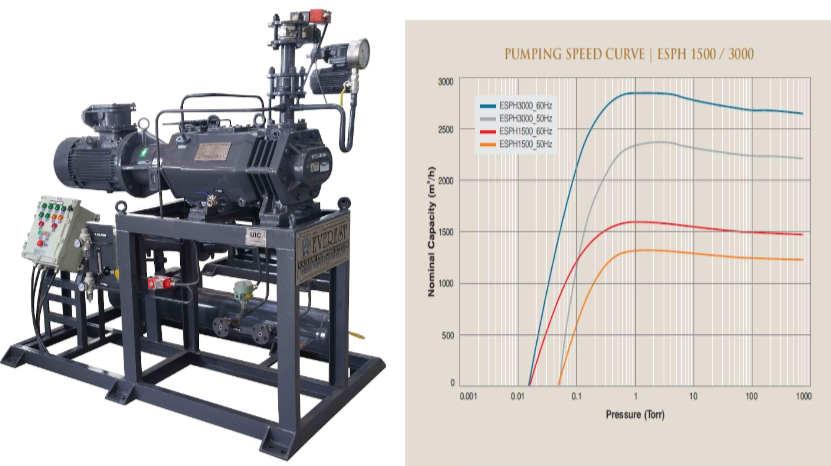

We have successfully installed & commissioned our Superscrew Dry screw vacuum pumps in various food industries and the reliable performance has resulted in significant savings in Operations/Process Utility Cost, compared to existing wet systems. Our ESPH Dry Screw Vacuum Pumps have catered to the needs of various segments in the food processing industry like Vacuum packaging of fresh and cooked meat, freeze drying, Deodorization of Vegetable oil (FFA Distillation), Sugar Refining, Vacuum Evaporative Cooling, Vacuum Tray Drying, Flash Drying etc.

We provide tailor made skid mounted systems where the Dry screw vacuum pump is equipped with accessories like Mechanical Vacuum Booster, Condensers, Vacuum Traps, Heat Exchangers etc as per the requirement and process of the customer.

Please let us know a suitable time and we would love to schedule a One to One call with you and our Vacuum specialist.

Tel:+91-9818742743

Website-www.everestvacuum.com

Everest Vacuum,

DSM 225-227, DLF Tower,

Moti Nagar, New Delhi-110015, India